OpenEMS Simulation Configuration Steps

This guide provides step-by-step instructions for setting up and debugging OpenEMS simulations.

Step 1: Simulator App

- Action:

- Check

enable. - Click

save.

- Check

- Notes:

- This will clear all existing configurations. Ensure no critical data is lost before proceeding.

- After clearing, all essential settings must be reconfigured in sequence.

Step 2: Scheduler (All Alphabetically)

- Settings:

ComponentID: scheduler0- Check

enable. - Click

save.

- Functionality:

- Automatically starts the following core components in alphabetical order:

coreess powerevcs powerController Api Websocketlog

- No additional configuration required to ensure basic system functionality.

- Automatically starts the following core components in alphabetical order:

Step 3: Controller Debug Log

- Settings:

ComponentID: ctrlDebugLog0- Check

enableandCondensed output.

- Functionality:

- Enables debugging mode with condensed logs for troubleshooting and system analysis.

Step 4: Simulator DataSource (CSV Predefined)

Configure three data sources to simulate load, PV generation, and ESS data.

-

Load Meter Data Source:

ComponentID: datasource0- Configuration:

- Check

enable. Factor: 10000Time-Delta: -1Source: h0-summer-weekday-standard-load-profile.csv

- Check

-

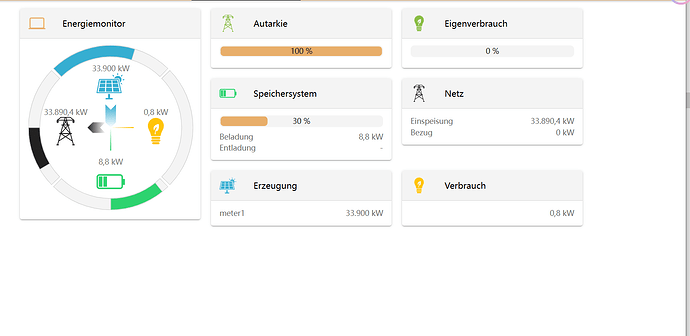

PV Meter Data Source:

ComponentID: datasource1- Configuration:

- Check

enable. Factor: 10000Time-Delta: -1Source: h0-summer-weekday-pv-production.csvorproduction2.

- Check

-

ESS Data Source:

ComponentID: datasource2- Configuration:

- Check

enable. Factor: 10000Time-Delta: -1Source: h0-summer-weekday-pv-production2.csv.

- Check

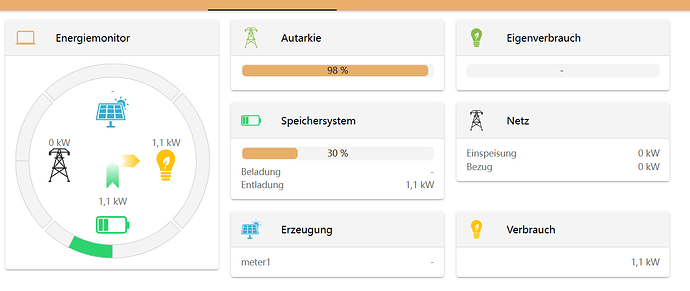

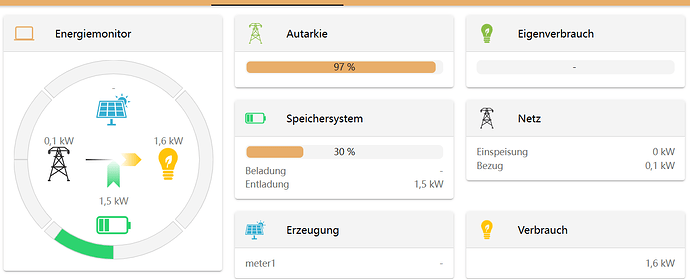

Step 5: Simulator GridMeter Acting

- Settings:

ComponentID: gridmeter0- Check

enable.

- Functionality:

- Simulates grid monitoring, providing data on grid power, state, and flow direction.

Step 6: Simulator EssSinglePhase Reacting

- Settings:

ComponentID: ess0Phase: L1(single-phase setup; use L2 for two-way or L3 for three-phase setups).Datasource-ID: datasource2Max Apparent Power [VA]: 10000Capacity [Wh]: 10000Initial State of Charge [%]: 30Grid mode: On_Grid(enables grid interaction).

- Functionality:

- Activates a single-phase ESS to simulate power response.

Step 7: Controller Ess Balancing

- Settings:

ComponentID: ctrlBalancing0- Configuration:

Energy System ID: ess0(matches Step 6).Grid Meter ID: gridmeter0(matches Step 5).Target Grid Setpoint: 10.

- Functionality:

- Controls ESS and grid meter to maintain balanced power flow.

Step 8: Controller Api Websocket

- Check:

- Ensure WebSocket is enabled.

- Functionality:

- Facilitates communication between OpenEMS and the UI.

- The UI will not display system status if WebSocket is disabled.

Step 9: Simulator Battery

- Settings:

ComponentID: bms0- Check

enable. - Configure parameters:

Number of slaves: 1Discharge min voltage: 44Charge max voltage: 56Discharge max current: 50Charge max current: 50SOC: 75SOH: 95Temperature: 30Capacity KWh: 50Voltage: 5Min cell voltage mv: 3300.

- Functionality:

- Activates the battery simulator with customizable parameters.

Step 10: Simulator NRCMeter Acting

- Settings:

ComponentID: meter0- Check

enable. - Configuration:

Datasource-ID: datasource0.

- Functionality:

- Activates load meter simulation, linked to

datasource0.

- Activates load meter simulation, linked to

Step 11: Simulator Production Meter Acting

- Settings:

ComponentID: meter1- Check

enable. - Configuration:

Datasource-ID: datasource1.

- Functionality:

- Activates PV meter simulation, linked to

datasource1.

- Activates PV meter simulation, linked to

Additional Recommendations

-

Step-by-Step Validation:

- Save after adding or modifying each component.

- Use the OpenEMS WebSocket interface to verify component statuses incrementally.

-

Log Monitoring:

- Enable debug logs (Step 3) for detailed analysis of system interactions.

-

Simulation Flexibility:

- Adjust parameters like battery capacity, power limits, and load curves to better simulate real scenarios.

-

Advanced Features:

- Use custom data sources or scripts for extended simulation, e.g.:

- EV charging load simulations.

- Fault condition testing (e.g., disconnections, overload).

- Use custom data sources or scripts for extended simulation, e.g.:

By completing the above steps, the simulation system will be ready for testing and validation of complex scenarios.